Non-Rising Stem Gate Valve Wholesale: A Detailed Guide for Buyers

2025-12-30

Welcome to our comprehensive guide on non-rising stem gate valves—a crucial component in various industrial applications. As you navigate the complexities of sourcing the right valves for your projects, understanding the nuances of these devices can make all the difference in efficiency and reliability. That's where DRIFCO comes in, offering expert insights and high-quality wholesale options to meet your needs. In this blog, we'll delve into the key features, benefits, and buying considerations for non-rising stem gate valves, helping you make informed decisions that enhance your operations. Whether you're a seasoned pro or new to the field, this guide is designed to spark your curiosity and set the stage for valuable, actionable information. Let's dive in and explore how the right valve choices can transform your business.

Understanding Non-Rising Stem Gate Valve Mechanics for Better Procurement

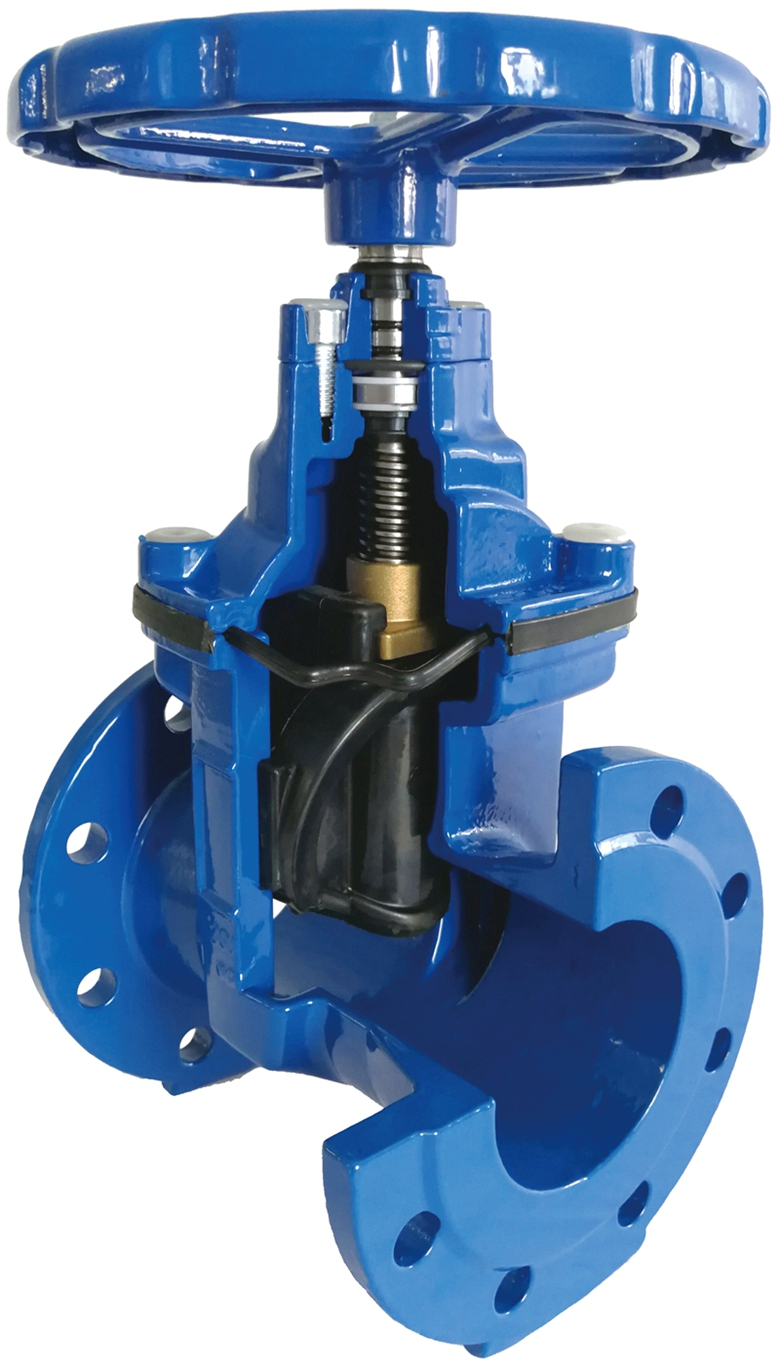

When procuring non-rising stem gate valves, grasping their mechanics is key to selecting the right fit for your application. Unlike rising stem models, where the stem moves up as the valve opens, non-rising stem valves keep the stem stationary within the body, with the gate rotating. This design minimizes space requirements and reduces wear on sealing surfaces, making them ideal for tight installations like underground pipelines or confined equipment setups. Understanding this mechanism helps avoid costly mismatches and ensures smoother procurement decisions.

The internal mechanics involve a threaded connection between the stem and gate, allowing the gate to move linearly without external stem motion. This setup often incorporates features like robust packing around the stem to prevent leaks, enhancing reliability in high-pressure or corrosive environments. By delving into these details, buyers can better assess factors like maintenance needs and compatibility with specific fluids, leading to more informed and efficient procurement that prioritizes long-term performance over just upfront costs.

For procurement teams, focusing on non-rising stem mechanics offers a competitive edge in sourcing. It enables tailored requests for quotes, emphasizing critical aspects such as material durability, stem alignment, and ease of operation. This deeper insight not only streamlines vendor comparisons but also fosters stronger supplier relationships by demonstrating technical expertise, ultimately resulting in higher-quality valve selections and improved operational outcomes in industrial systems.

Key Material Choices in Non-Rising Stem Valves and Their Impact

When selecting materials for non-rising stem valves, engineers often prioritize durability and corrosion resistance, especially in harsh environments like chemical processing or offshore applications. Common choices include stainless steel, which offers excellent strength and anti-corrosive properties, and exotic alloys like Hastelloy or Monel, tailored for extreme conditions where standard materials might fail. The material directly influences the valve's lifespan and maintenance intervals, with higher-grade alloys typically reducing downtime and repair costs over time.

Beyond just durability, material selection affects the valve's operational efficiency and safety. For instance, using softer materials like brass or bronze in non-rising stem designs can provide better sealing capabilities and reduce the risk of stem galling, a common issue in high-friction scenarios. However, these materials might not hold up well under high-pressure or abrasive media, leading to potential leaks or failures if mismatched to the application's demands.

In recent years, advancements in composite materials and coatings have introduced new options, such as PTFE-lined stems or ceramic components, which enhance wear resistance and chemical inertness. These innovations allow for customized solutions that balance cost, performance, and environmental factors, making it crucial to assess the specific fluid, temperature, and pressure conditions before finalizing a material choice to ensure optimal valve functionality and reliability.

Navigating Global Standards and Certifications for Valve Wholesalers

In today's interconnected industrial landscape, valve wholesalers must navigate a complex web of global standards and certifications to ensure compliance, quality, and market access. Key organizations like the American Petroleum Institute (API), International Organization for Standardization (ISO), and European Pressure Equipment Directive (PED) set rigorous benchmarks that influence everything from material selection to performance testing. For wholesalers, understanding these frameworks isn't just about ticking boxes – it's about building trust with clients across sectors like oil and gas, water treatment, and manufacturing, where reliability can make or break operational safety.

Beyond merely stocking certified products, savvy wholesalers actively engage in the certification process by partnering with manufacturers who prioritize third-party audits and continuous improvement. This involves staying updated on evolving regulations, such as API 6D for pipeline valves or ISO 15848 for fugitive emissions, which are increasingly critical in environmentally conscious markets. By offering detailed documentation and traceability, wholesalers can differentiate themselves as knowledgeable intermediaries, helping clients avoid costly delays or compliance pitfalls in international projects.

To truly stand out, forward-thinking valve wholesalers go beyond standard compliance by embracing niche certifications tailored to specific industries or regions. For instance, certifications like the ASME Boiler and Pressure Vessel Code or the WRAS approval for water fittings can open doors to specialized markets. By curating a portfolio that highlights these credentials and providing expert guidance on their applications, wholesalers not only facilitate smoother procurement but also position themselves as indispensable partners in a competitive global supply chain.

Cost-Effective Sourcing Strategies in the Valve Wholesale Market

When it comes to securing cost-effective valves in the wholesale market, many businesses focus solely on price tags, but the real game-changer lies in strategic sourcing approaches. For instance, building long-term partnerships with manufacturers can lead to volume discounts and priority access to new inventory, reducing overall procurement costs without sacrificing quality. Additionally, considering alternative materials like composite or thermoplastic valves for non-critical applications can slash expenses while maintaining functionality—a simple shift that often goes overlooked in traditional sourcing models.

Another underutilized tactic involves leveraging regional sourcing hubs in areas like Southeast Asia or Eastern Europe, where production costs are lower but technical expertise remains high. This allows wholesalers to tap into competitive pricing without the usual trade-offs in reliability. Don't forget to analyze total cost of ownership too; a slightly pricier valve with better durability and minimal maintenance might save more in the long run than a cheap, high-failure-rate option.

To stand out, savvy wholesalers are now integrating data analytics into their sourcing workflows, using historical purchasing data to predict market trends and negotiate better deals proactively. This forward-thinking move not only cuts costs but also builds resilience against supply chain disruptions, making it a key differentiator in a crowded marketplace. Remember, effective sourcing isn't just about finding the lowest bid—it's about crafting a smart, adaptable strategy that balances cost, quality, and risk for sustained success.

Installation and Maintenance Tips to Extend Valve Lifespan

To boost valve durability right from the start, meticulous installation is critical. Ensure proper alignment by using precise measurement tools, avoiding missteps that can lead to premature wear. Lubricate moving parts with a manufacturer-recommended product, and torque bolts evenly to prevent stress concentrations. Consider environmental factors like temperature variations or corrosive atmospheres; using compatible materials and sealing techniques tailored to these conditions can make a significant difference in long-term performance.

Regular upkeep is just as vital as correct installation. Implement a routine inspection schedule, checking for signs of leakage, corrosion, or unusual noises during operation. Keep valves clean by removing debris and buildup that might hinder movement, using non-abrasive methods to avoid surface damage. Adjustments, if needed, should follow guidelines closely—overtightening or skipping steps often causes more harm than neglect.

For those in high-demand applications, proactive strategies like predictive maintenance can further enhance lifespan. Monitor pressure and flow rates with digital sensors to detect anomalies early, allowing timely interventions before failures occur. Train personnel on best practices, emphasizing gentle handling and proper storage when valves are not in use. By blending careful installation with attentive care, you'll not only extend valve life but also improve overall system reliability.

Emerging Trends and Innovations in Non-Rising Stem Valve Technology

As industries increasingly prioritize efficiency and space optimization, non-rising stem valves are seeing a surge in innovative materials that enhance durability and performance. Manufacturers are now experimenting with advanced composites and coatings that resist corrosion in harsh environments, such as offshore oil rigs or chemical processing plants. This shift not only extends valve lifespan but also reduces maintenance needs, making them a cost-effective solution over time.

Another key trend is the integration of smart technology into these valves, enabling real-time monitoring and predictive maintenance through IoT sensors. These innovations allow operators to track parameters like pressure and temperature remotely, minimizing downtime and preventing failures before they occur. This connectivity is revolutionizing how facilities manage their fluid control systems, moving from reactive to proactive strategies.

Beyond functionality, design improvements are making non-rising stem valves more versatile for compact applications. Engineers are developing sleeker profiles and modular components that fit into tight spaces without sacrificing flow control. This adaptability is particularly valuable in urban infrastructure and renewable energy projects, where space constraints demand creative solutions for reliable valve operation.

FAQ

A Non-Rising Stem Gate Valve features a stem that doesn't rise when operated, keeping the valve's height consistent. It's popular in wholesale because it saves space, reduces installation costs, and offers reliable flow control in compact settings like pipelines and industrial systems.

Look for certifications like API or ISO standards, check material grades such as stainless steel or bronze, and test for smooth operation and leak-proof design. Reviewing supplier reputation and sample testing can help avoid low-quality batches.

They're commonly used in water treatment plants, oil and gas pipelines, HVAC systems, and chemical processing. Their compact design makes them ideal for tight spaces where rising stems might interfere or cause safety issues.

Non-Rising Stem valves have a stem that rotates in place without moving up, suitable for limited spaces. Rising Stem valves have a stem that lifts visibly with operation, which helps indicate position but requires more vertical room; choice depends on installation constraints.

Consider the fluid type, pressure, temperature, and corrosion risks. Options include brass for general use, stainless steel for harsh environments, and PVC for chemical resistance; matching material to application ensures durability and safety.

Regularly inspect for wear, lubricate the stem threads, check for leaks, and clean debris from the valve body. Following manufacturer guidelines and scheduling periodic maintenance prevents failures in critical systems.

Compare quotes from multiple suppliers, order in larger quantities for volume discounts, and consider standard models over custom ones. Negotiate warranties and after-sales support to balance cost with long-term value.

Advancements include smart valves with IoT sensors for real-time monitoring, improved sealing technologies to reduce leaks, and eco-friendly materials. These innovations enhance efficiency and adaptability in modern industrial applications.

Conclusion

For wholesalers navigating the complex market of non-rising stem gate valves, a deep understanding of valve mechanics is essential for making informed procurement decisions. These valves operate with a stem that rotates but does not lift, making them ideal for confined spaces where clearance is limited. By grasping how the stem interacts with the gate and seat, buyers can better assess valve performance in applications such as water supply, oil and gas, or industrial processing. This mechanical insight directly ties into material selection, where choices like bronze, stainless steel, or cast iron impact durability and cost-effectiveness. For instance, stainless steel offers superior corrosion resistance in harsh environments, while bronze might be more economical for general use. Integrating this knowledge helps wholesalers source valves that not only meet functional needs but also align with global standards, ensuring reliability and compliance across diverse markets.

To stay competitive, effective sourcing strategies must go beyond initial costs, considering long-term value through proper installation and maintenance. Simple tips like ensuring proper alignment during installation and regular lubrication can significantly extend valve lifespan, reducing replacement frequency and downtime for end-users. Meanwhile, emerging trends in valve technology, such as smart valves with IoT integration or advanced sealing materials, present opportunities for wholesalers to offer innovative solutions. By keeping abreast of these developments and navigating certifications like API or ISO, buyers can differentiate their offerings in a crowded market. Ultimately, a holistic approach that blends technical understanding, strategic sourcing, and awareness of innovations empowers wholesalers to provide high-quality, cost-effective non-rising stem gate valves that meet evolving customer demands, driving business growth and customer satisfaction.

Contact Us

Contact Person: George

Email: [email protected]

Tel/WhatsApp: 13863633883

Website: https://www.es-fire.com