Boosting Energy Efficiency: How the 12A Middle Glass Warm Edge Spacer Enhances Window Thermal Performance

2024-05-24

In the quest for more energy-efficient buildings, one key component often overlooked is the humble window spacer. The 12A Middle Glass Warm Edge Spacer is a standout in this regard, offering significant improvements in thermal performance for windows. But how exactly does it work? Let’s delve into the science and benefits behind this innovative spacer.

Understanding Warm Edge Technology

Traditionally, window spacers were made from aluminum, a material known for its high thermal conductivity. While aluminum spacers provide structural support, they also create a thermal bridge, allowing heat to escape during the winter and enter during the summer. This inefficiency leads to increased energy consumption for heating and cooling.

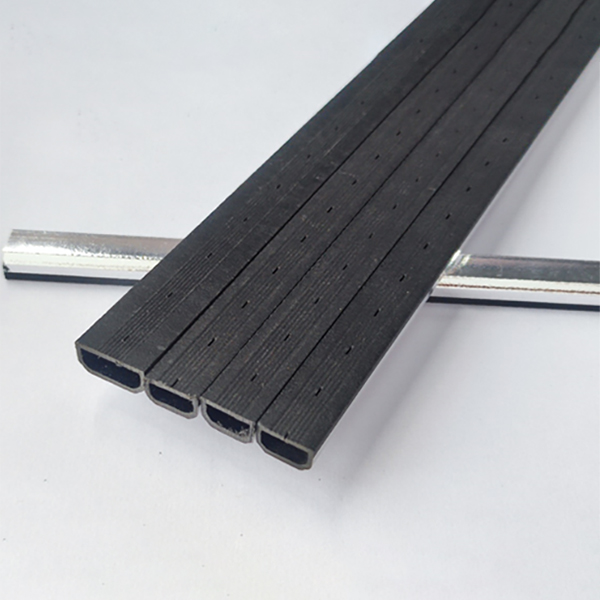

Warm edge spacers, such as the 12A Middle Glass Warm Edge Spacer, are designed to combat this issue. They are made from materials with low thermal conductivity, significantly reducing heat transfer and improving the overall thermal efficiency of the window.

Key Features of the 12A Middle Glass Warm Edge Spacer

1. Low Thermal Conductivity Materials:

The core material of the 12A spacer is a polymeric composite, which has much lower thermal conductivity than traditional aluminum. This material choice is crucial because it minimizes the thermal bridge effect, maintaining a more consistent indoor temperature.

2. Desiccant Integration:

Inside the spacer, desiccants are used to absorb moisture. This is vital for preventing condensation within the insulated glass unit (IGU). Condensation can not only reduce visibility but also compromise the thermal efficiency of the window by allowing more heat transfer.

3. Improved Sealants:

The 12A spacer uses advanced adhesives and sealants to bond with the glass panes. These sealants are flexible and durable, ensuring that the spacer maintains an airtight seal despite thermal expansion and contraction. This airtight seal is essential for maintaining the insulating properties of the IGU.

How the 12A Middle Glass Warm Edge Spacer Enhances Thermal Performance

1. Reduction of Heat Transfer:

By using materials with low thermal conductivity, the 12A spacer dramatically reduces the amount of heat that can pass through the edge of the window. This reduction in heat transfer is key to improving the overall thermal performance of the window, making it more energy-efficient.

2. Minimization of Condensation:

Condensation can occur when the interior surface of the window is significantly cooler than the room temperature. The 12A spacer helps to keep the edge of the glass warmer, reducing the likelihood of condensation forming. This not only improves visibility and comfort but also maintains the window's insulating properties.

3. Enhanced Energy Efficiency:

By reducing heat loss in the winter and heat gain in the summer, the 12A spacer helps to lower energy consumption for heating and cooling. This can lead to significant cost savings over time, especially in climates with extreme temperatures.

4. Increased Comfort:

Improved thermal performance translates to a more consistent indoor temperature. Homeowners and occupants will experience fewer drafts and cold spots near windows, enhancing overall comfort.

5. Environmental Impact:

With better energy efficiency, buildings using the 12A spacer contribute to lower greenhouse gas emissions. This is an important step towards more sustainable building practices and reducing the carbon footprint of buildings.

Conclusion

The 12A Middle Glass Warm Edge Spacer is a critical innovation in window technology, offering substantial improvements in thermal performance. By utilizing low thermal conductivity materials, integrating effective desiccants, and employing advanced sealants, this spacer addresses the key issues of heat transfer and condensation. The result is a more energy-efficient, comfortable, and environmentally friendly building.

As the demand for sustainable building solutions grows, technologies like the 12A Middle Glass Warm Edge Spacer will play an increasingly vital role in achieving energy efficiency goals. Whether for residential or commercial applications, the benefits of improved thermal performance are clear: lower energy costs, enhanced comfort, and a smaller environmental footprint.