Enhancing Efficiency in Manufacturing with Intelligent Factory Supply Automated Edge Banding Cell

2024-07-02

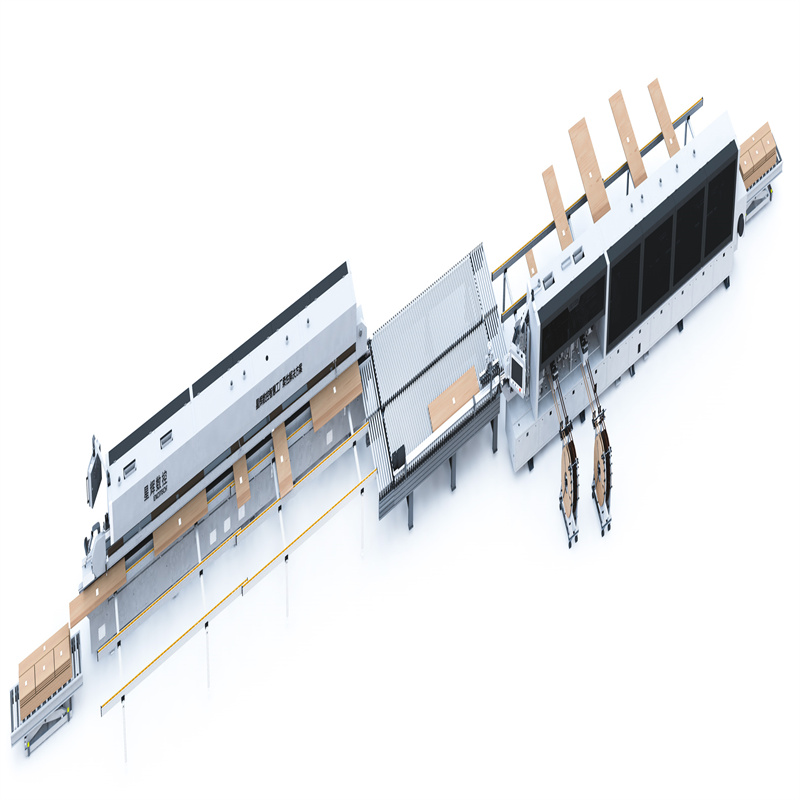

Efficiency is a critical factor in manufacturing, directly impacting production costs, time-to-market, and overall competitiveness. The Intelligent Factory Supply Automated Edge Banding Cell is a groundbreaking solution designed to optimize edge banding processes, thereby enhancing efficiency across the manufacturing floor. This blog delves into how this advanced technology is transforming manufacturing efficiency.

Understanding the Edge Banding Process

Edge banding is an essential finishing process in the production of various materials, particularly in woodworking and furniture manufacturing. It involves applying a narrow strip of material to cover and protect the exposed edges of boards, enhancing their appearance and durability. Traditional edge banding methods can be time-consuming and labor-intensive, often leading to inefficiencies in production.

The Role of Intelligent Factory Supply Automated Edge Banding Cell

The Intelligent Factory Supply Automated Edge Banding Cell automates the edge banding process, incorporating advanced technologies to streamline operations and boost efficiency. Key features of this automated solution include:

1. Automated Material Handling

The automated cell is equipped with robotic arms and conveyors that handle materials with precision and speed. This automation reduces manual handling, minimizing errors and increasing throughput.

2. Advanced Sensor Technology

High-precision sensors monitor the edge banding process in real-time, ensuring accurate application and immediate detection of any anomalies. This level of monitoring helps maintain consistent quality and reduces the need for rework.

3. Efficient Adhesive Application

The automated edge banding cell uses sophisticated adhesive application systems that apply the right amount of adhesive evenly, reducing waste and ensuring strong, durable bonds.

4. Seamless Integration with Production Lines

Designed to integrate seamlessly with existing production lines, the Intelligent Factory Supply Automated Edge Banding Cell can be easily incorporated into various manufacturing setups, enhancing overall workflow efficiency.

Benefits of Enhanced Efficiency

The implementation of the Intelligent Factory Supply Automated Edge Banding Cell brings several efficiency-related benefits to manufacturers:

1. Increased Production Speed

Automation significantly accelerates the edge banding process, enabling manufacturers to produce more units in less time. This increased speed translates to higher production capacity and faster fulfillment of orders.

2. Reduced Downtime

The automated cell's reliability and real-time monitoring capabilities minimize downtime due to maintenance or quality issues. This ensures a smoother production process with fewer interruptions.

3. Optimized Resource Utilization

By automating material handling and adhesive application, manufacturers can optimize the use of resources, reducing waste and improving cost-efficiency.

4. Enhanced Workforce Productivity

With automation handling repetitive and labor-intensive tasks, the workforce can be redirected to more value-added activities, such as quality control, process improvement, and innovation.

Conclusion

The Intelligent Factory Supply Automated Edge Banding Cell is a game-changer for manufacturers seeking to enhance efficiency in their production processes. By automating key aspects of edge banding, this advanced solution reduces manual labor, speeds up production, and optimizes resource utilization. As manufacturers continue to adopt intelligent automation technologies, the benefits of increased efficiency will drive industry growth and competitiveness.