Enhancing Efficiency: The Crucial Role of Steel Chimney Design in Steel Factory Operations

2024-04-11

In the bustling world of steel manufacturing, efficiency is the name of the game. Every aspect of the production process, from raw material handling to finished product distribution, must be optimized to ensure maximum productivity and profitability. Amidst the array of equipment and machinery in a steel factory, one often overlooked component plays a critical role in driving efficiency: the steel chimney.

A Vertical Conduit for Efficiency:

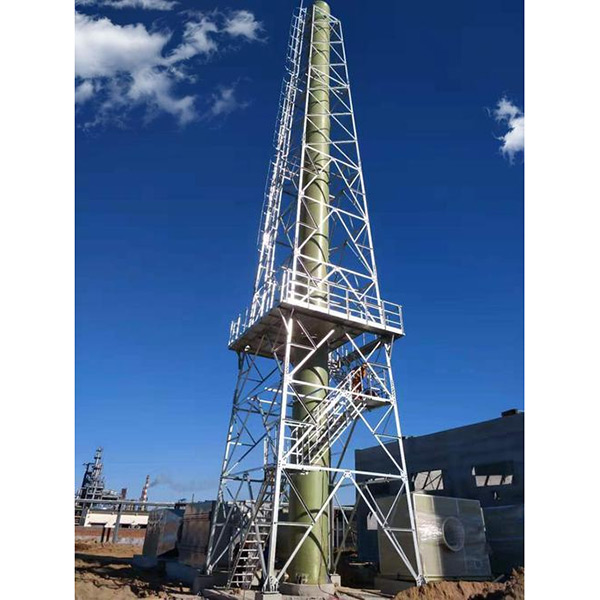

The design of a steel chimney is far from arbitrary; it is meticulously crafted to enhance the overall efficiency of a steel factory. At its core, a steel chimney serves as a vertical conduit for the by-products and emissions generated during the steelmaking process. However, its impact extends far beyond simply venting gases into the atmosphere.

Optimizing Airflow and Ventilation:

One of the primary ways in which the design of a steel chimney contributes to factory efficiency is by optimizing airflow and ventilation. Within the confines of a steel factory, maintaining proper airflow is crucial for several reasons. Firstly, it ensures the efficient combustion of fuels in furnaces and other equipment, maximizing energy utilization and minimizing waste. Additionally, proper ventilation helps regulate temperature and humidity levels, creating a more stable and comfortable working environment for factory personnel.

Minimizing Downtime and Disruptions:

A well-designed steel chimney also plays a key role in minimizing downtime and disruptions to production processes. By effectively venting emissions away from critical equipment and production areas, the risk of contamination or damage to machinery is reduced. This helps prevent costly shutdowns and delays, allowing the factory to operate smoothly and consistently.

Environmental Compliance and Sustainability:

In today's environmentally conscious world, the design of a steel chimney is also closely tied to sustainability and regulatory compliance. By directing emissions through the chimney, factories can effectively control and monitor their environmental footprint. This not only helps ensure compliance with emissions regulations but also demonstrates a commitment to environmental stewardship and sustainability.

Structural Integrity and Reliability:

Of course, efficiency is not solely determined by airflow dynamics and environmental considerations; structural integrity and reliability are also paramount. The design of a steel chimney must account for factors such as wind loads, seismic activity, and corrosion resistance to ensure long-term performance and durability. A well-engineered chimney can withstand the rigors of industrial operation, providing reliable service for years to come.

Conclusion:

In the intricate dance of steel manufacturing, every component plays a vital role in driving efficiency and productivity. The design of a steel chimney may seem like a small detail in the grand scheme of factory operations, but its impact is anything but insignificant. By optimizing airflow, minimizing disruptions, ensuring environmental compliance, and maintaining structural integrity, a well-designed steel chimney contributes to the overall efficiency and success of a steel factory. As the steel industry continues to evolve, the importance of thoughtful chimney design will only become more pronounced, serving as a beacon of efficiency in an ever-changing landscape.