Exploring the Diversity of Printer Ribbons: A Guide to Different Types Available in the Market

2024-03-12

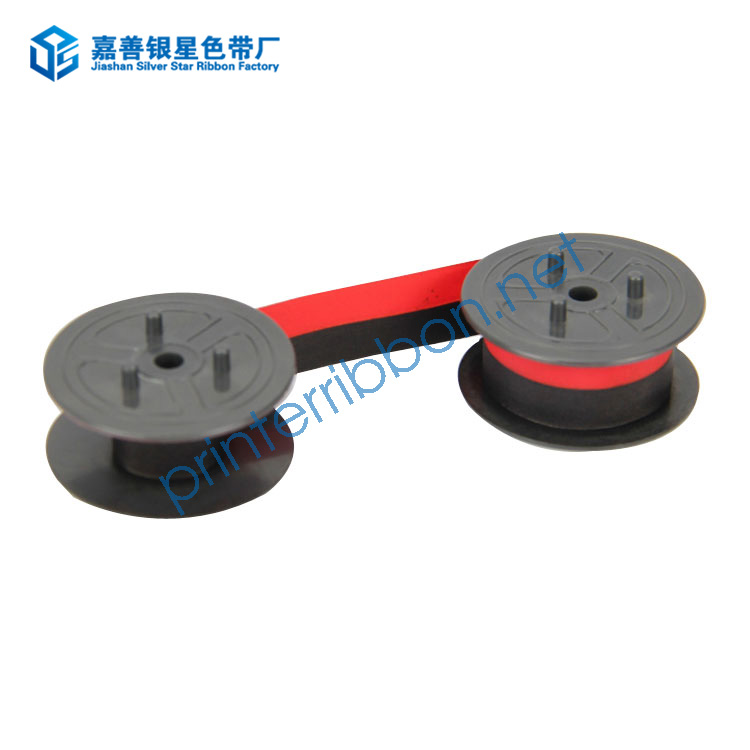

In the realm of printing technology, printer ribbons play a crucial role in producing high-quality prints for various applications. From dot matrix to line matrix printers, these ribbons come in a variety of types, each tailored to specific printing needs and preferences. In this blog post, we will explore the different types of printer ribbons available in the market, highlighting their characteristics and applications.

Nylon printer ribbons are among the most common types used in dot matrix printers. They are characterized by their durability and versatility, making them suitable for high-volume printing tasks. Nylon ribbons typically feature a single-color ink, such as black, and are compatible with a wide range of dot matrix printers.

Applications: Accounting documents, invoices, shipping labels, and forms.

2. Fabric Printer Ribbons

Fabric printer ribbons are similar to nylon ribbons but are made from woven fabric materials instead. They offer enhanced durability and longevity compared to nylon ribbons, making them ideal for applications requiring long-lasting prints. Fabric ribbons are available in various colors, allowing for multi-color printing capabilities.

Applications: Receipts, invoices, tickets, and multipart forms.

3. Film Printer Ribbons

Film printer ribbons are designed for high-speed line matrix printers, offering superior print quality and consistency. They feature a special film substrate coated with ink or pigment, resulting in sharp and precise prints. Film ribbons are available in both monochrome and color options, catering to diverse printing requirements.

Applications: Barcodes, shipping labels, packing slips, and invoices.

4. Wax Ribbons

Wax ribbons are commonly used in thermal transfer printers, where heat is applied to transfer ink onto the printing surface. They are characterized by their low melting point and excellent print quality on paper labels and tags. Wax ribbons are available in different formulations, including standard wax, enhanced wax, and color wax, to accommodate various printing needs.

Applications: Product labels, asset tags, retail tags, and shipping labels.

5. Wax-Resin Ribbons

Wax-resin ribbons combine the durability of resin ribbons with the versatility of wax ribbons, offering enhanced resistance to abrasion, chemicals, and harsh environmental conditions. They provide crisp and durable prints on a wide range of substrates, including paper, synthetic materials, and films.

Applications: Pharmaceutical labels, chemical drum labels, outdoor signage, and asset tracking labels.

6. Resin Ribbons

Resin ribbons are engineered for demanding applications requiring maximum durability and resistance to harsh conditions. They feature a high-melt-point formulation that ensures long-lasting prints, even in extreme environments. Resin ribbons are commonly used in industrial and specialty printing applications where durability and longevity are paramount.

Applications: Automotive labels, electronic component labels, chemical labels, and outdoor signage.

Conclusion

The diversity of printer ribbons available in the market reflects the varied needs and preferences of users across different industries and applications. Whether you require durable prints for industrial labeling or vibrant colors for retail tags, there is a printer ribbon suited to your specific requirements. By understanding the characteristics and applications of different types of printer ribbons, you can make informed decisions when selecting the most suitable option for your printing needs.