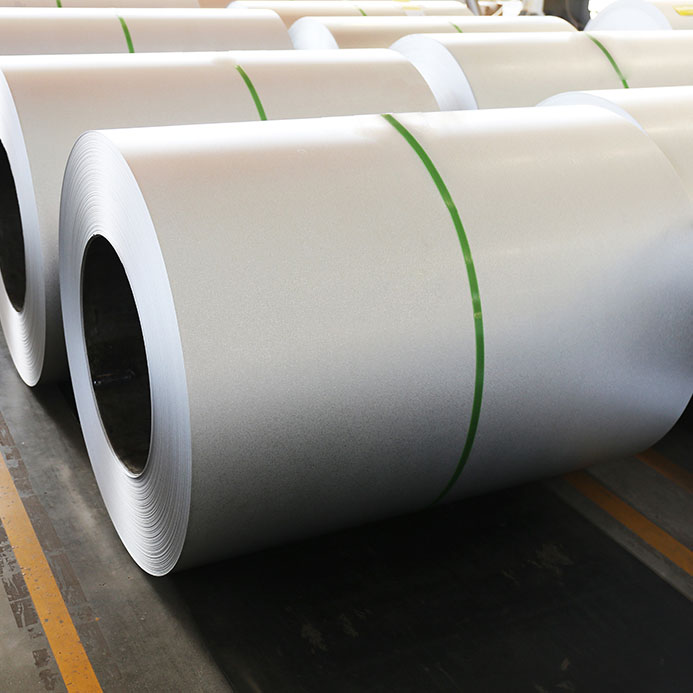

Exploring the Unique Color Coating Process of SECE Color Coated Galvanized Steel Coil

2024-04-25

In the world of steel manufacturing, innovation is constantly pushing the boundaries of what's possible. One such innovation is the SECE Color Coated Galvanized Steel Coil, which combines the corrosion resistance of traditional galvanization with vibrant color options. But how does the color coating process of SECE differ from traditional galvanization? Let's dive into the details to understand this transformative process.

Traditional Galvanization

Before delving into the color coating process, it's essential to understand traditional galvanization. Galvanization involves applying a layer of zinc to steel to protect it from corrosion. This process typically entails dipping the steel substrate into a bath of molten zinc or electroplating it with zinc.

While traditional galvanization provides excellent corrosion protection, it leaves the steel with a metallic gray appearance. This limitation led to the development of color coating processes to enhance aesthetics while maintaining the protective properties of galvanized steel.

The Color Coating Process of SECE Color Coated Galvanized Steel Coil

The color coating process of SECE Color Coated Galvanized Steel Coil builds upon traditional galvanization by adding a layer of color coating on top of the zinc layer. Here's how it differs:

1. Preparation of the Substrate: Just like traditional galvanization, the steel substrate undergoes thorough cleaning and surface preparation to ensure optimal adhesion of the coatings.

2. Application of Primer: Unlike traditional galvanization, which may or may not include a primer, the color coating process of SECE often begins with the application of a primer layer. The primer helps enhance adhesion between the zinc coating and the subsequent layers.

3. Color Coating Application: After the primer, the steel coil passes through a coating line where the color coating is applied. The color coating is a specialized formulation consisting of pigments, resins, binders, and additives. This coating not only adds vibrant color but also provides additional protection against UV radiation, weathering, and abrasion.

4. Curing: Once the color coating is applied, the steel coil undergoes a curing process, typically through high-temperature baking. This ensures the proper bonding and curing of the coating layers, resulting in a durable finish.

5. Quality Control: Throughout the process, strict quality control measures are implemented to ensure uniform coating thickness, color consistency, and overall product quality.

Key Differences and Advantages

The primary difference between traditional galvanization and the color coating process of SECE lies in the addition of the color coating layer. This layer not only enhances aesthetics but also provides additional protection against environmental factors.

- Aesthetics: SECE Color Coated Galvanized Steel Coil offers a wide range of color options, allowing for customized designs and architectural applications.

- Durability: The color coating adds an extra layer of protection against UV radiation, corrosion, and abrasion, increasing the lifespan of the steel coil.

- Versatility: With its combination of corrosion resistance and vibrant color options, SECE Color Coated Galvanized Steel Coil finds applications in architecture, automotive, appliances, and more.

In conclusion, the color coating process of SECE Color Coated Galvanized Steel Coil transforms traditional galvanized steel into a versatile and aesthetically pleasing material suitable for a wide range of applications. By adding vibrant colors and additional protection, this innovative process opens up new possibilities for designers, architects, and manufacturers alike.