The Evolution of Heat Exchange: Introducing Next-Gen Aluminium Microchannel Tubes

2025-09-28

Table of Contents

-

The Evolution of Heat Exchange: Introducing Next-Gen Aluminium Microchannel Tubes

-

Core Technical Specifications and Performance Parameters

-

Advantages Over Traditional Copper Tubes

-

Manufacturing Process and Quality Assurance

-

Applications Across Industries

-

Frequently Asked Questions (FAQ)

The Evolution of Heat Exchange: Introducing Next-Gen Aluminium Microchannel Tubes

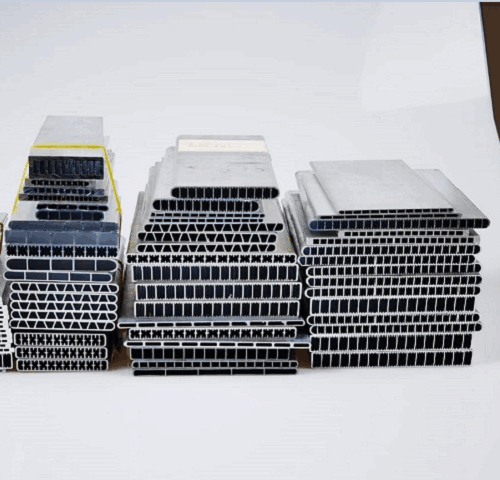

The landscape of heat transfer technology has been fundamentally reshaped by the advent and continuous refinement of the Aluminium Microchannel Tube. For decades, the industry relied heavily on traditional round copper tubes. However, driven by the global demand for higher efficiency, reduced environmental impact, and superior material performance, a significant technological shift has occurred. The latest generation of Aluminium Microchannel Tubes represents the pinnacle of this evolution, offering an unparalleled combination of thermal conductivity, structural integrity, and lightweight design. This article delves into the technical upgrades that define these advanced components.

Core Technical Specifications and Performance Parameters

The superiority of our upgraded Aluminium Microchannel Tube is rooted in its precise engineering and material science. The following parameters are critical for engineers and OEM designers to understand its capabilities.

Key Product Parameters:

-

Material: High-Purity Aluminium Alloy (AA3003 or equivalent)

-

Standard Wall Thickness: 0.4mm - 0.8mm (customizable)

-

Hydraulic Diameter: 0.5mm - 2.0mm

-

Port Count: Typically 8 to 24 ports, configurable based on application

-

Tube Width: 16mm, 18mm, 20mm (standard)

-

Tube Height: 1.2mm - 2.5mm

-

Standard Length: Custom cut from 100mm to 12 meters

-

Max Working Pressure: > 120 Bar

-

Burst Pressure: > 350 Bar

The table below provides a clear comparison of performance metrics against a baseline model, highlighting the key upgrades:

| Feature | Previous Generation | Upgraded Aluminium Microchannel Tube | Improvement |

|---|---|---|---|

| Thermal Efficiency | Base (100%) | 25-40% Higher | Significant |

| Internal Surface Area | Standard | Optimized port geometry | +30% |

| Corrosion Resistance | Standard Coating | Enhanced hydrophilic coating | 3x Life |

| Refrigerant Charge | Base Requirement | Reduced volume design | -40% |

| Weight per Meter | Standard | Advanced thinning technology | -15% |

Advantages Over Traditional Copper Tubes

The technical upgrades embedded in the modern Aluminium Microchannel Tube translate into direct, tangible advantages that impact both manufacturing and end-user performance.

-

Enhanced Heat Transfer: The multi-port design creates a vastly larger surface area for heat exchange compared to a single round tube, leading to a dramatic increase in thermal efficiency.

-

Significant Weight Reduction: Aluminium is substantially lighter than copper. This reduces the overall weight of the heat exchanger, which is critical for applications like automotive HVAC and aerospace.

-

Superior Structural Strength: The rectangular, multi-port profile offers greater resistance to internal pressure and external physical stress than round tubes, enhancing durability and system longevity.

-

Reduced Refrigerant Usage: The smaller internal volume of the microchannels requires significantly less refrigerant to achieve the same cooling capacity, lowering costs and environmental impact.

-

Cost-Effectiveness: Aluminium is more abundant and cost-stable than copper, providing a more economical solution without compromising performance.

Manufacturing Process and Quality Assurance

The production of a high-quality Aluminium Microchannel Tube is a sophisticated process. It begins with the extrusion of high-purity aluminium alloy into the precise multi-channel profile. This is followed by a series of critical steps, including:

-

Precision Drawing: To achieve exact dimensional tolerances and a smooth internal surface.

-

Bending and Forming: Utilizing CNC technology to shape the tubes without collapsing the microchannels.

-

Brazing Preparation: Application of a controlled flux or cladding to ensure perfect joint integrity during assembly.

-

Leak Testing: 100% of tubes undergo rigorous helium mass spectrometry or pressure decay tests to guarantee zero defects.

This stringent manufacturing protocol ensures every tube delivers consistent, reliable performance under the most demanding conditions.

Applications Across Industries

The versatility of the upgraded tube makes it the component of choice for a wide range of applications.

-

Automotive: Radiators, condensers, and evaporators for electric and internal combustion engine vehicles.

-

HVAC&R: Residential and commercial air conditioning condensers and evaporators, commercial refrigeration units.

-

Aerospace: Environmental control systems and avionics cooling.

-

Industrial Machinery: Hydraulic oil coolers and process chillers.

Frequently Asked Questions (FAQ)

1. How does the corrosion resistance of aluminium compare to copper in these applications?

While copper is naturally corrosion-resistant, our upgraded Aluminium Microchannel Tube is treated with a proprietary hydrophilic coating. This coating not only enhances heat transfer but also provides exceptional resistance to salt spray, moisture, and other corrosive elements, often outperforming uncoated copper in harsh environments.

2. Are these tubes compatible with the latest eco-friendly refrigerants like R-454B and R-32?

Absolutely. The advanced aluminium alloy and brazing technology used in our tubes are specifically engineered to be fully compatible with modern, high-pressure, low-global-warming-potential (GWP) refrigerants. Their robust construction handles the required operating pressures with a significant safety margin.

3. Can we customize the dimensions and port configuration for a specific design?

Yes, customization is a core strength of our manufacturing process. We can tailor the tube's width, height, length, wall thickness, and the number of internal ports to meet the specific thermal and mechanical requirements of your unique application. Our engineering team is available to consult on optimal configurations.

If you are very interested in our company's products or have any questions, please feel free to contact us.