The Evolution of Process Automation in Feather Meal Equipment

2025-09-17

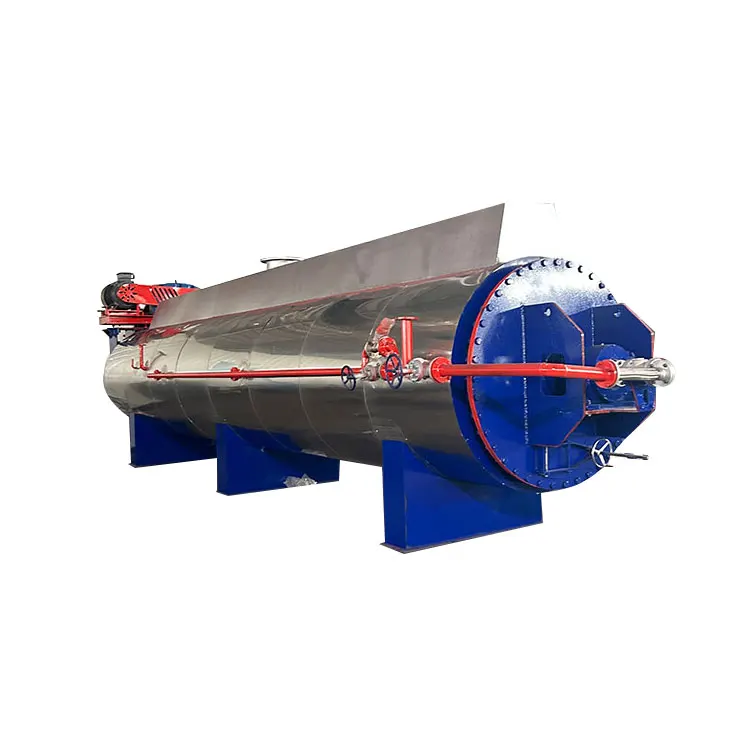

In the agricultural and animal by-product processing industry, efficiency and consistency are critical. The development of process automation has revolutionized feather meal production, enhancing productivity, safety, and output quality. Modern Feather Meal Equipment integrates advanced automation technologies to streamline operations, reduce labor costs, and ensure precise control over every production phase.

Automated systems now manage everything from raw material handling to drying, grinding, and packaging. This level of automation minimizes human error, optimizes energy consumption, and maximizes throughput. For businesses, this means higher profitability and compliance with stringent industry standards.

Key Features of Automated Feather Meal Equipment

Our automated Feather Meal Equipment is designed for durability, scalability, and ease of use. Below are some of the standout features:

-

PLC Control System: Centralized automation with touch-screen interface for real-time monitoring and adjustments.

-

Energy-Efficient Thermal Processing: Reduces fuel consumption while maintaining optimal temperature levels.

-

Automated Feeding and Discharge Systems: Ensures continuous operation with minimal manual intervention.

-

Safety Interlocks and Alarms: Protects equipment and operators by detecting anomalies instantly.

-

Data Logging and Reporting: Tracks production metrics for quality control and process optimization.

Technical Specifications

For a detailed overview, here are the standard parameters of our automated feather meal processing systems:

| Parameter | Specification | Benefits |

|---|---|---|

| Processing Capacity | 1-10 tons per hour (customizable) | Scalable for small to large production facilities |

| Power Requirement | 380V, 50/60Hz, 3-phase | Compatible with industrial power standards |

| Operating Temperature | 120°C - 150°C | Efficient sterilization and drying |

| Automation Level | Fully automated with PLC and SCADA support | Reduces manual labor, improves precision |

| Main Material | Stainless Steel (SS304/SS316) | Corrosion-resistant, hygienic, and durable |

| Moisture Reduction Rate | Up to 90% | Produces consistent, high-quality feather meal with low moisture content |

| Safety Features | Overheat protection, pressure release valves | Ensures safe operation under high-pressure conditions |

Advantages of Upgrading to Automated Systems

Investing in the latest Feather Meal Equipment with automation capabilities offers tangible benefits:

-

Improved Product Quality: Consistent processing conditions result in uniform nutrient composition and finer texture.

-

Higher Efficiency: Continuous operation shortens processing time and increases daily output.

-

Cost Savings: Lower energy and labor requirements lead to significant long-term savings.

-

Eco-Friendly Operation: Advanced systems include odor control and emissions reduction technologies.

Automation is no longer a luxury but a necessity for staying competitive in the feather meal industry. By embracing these technological advancements, producers can achieve new levels of operational excellence and product quality.