The Role of Single Head Cap Screwing Machine in Modern Packaging

2024-07-12

Introduction

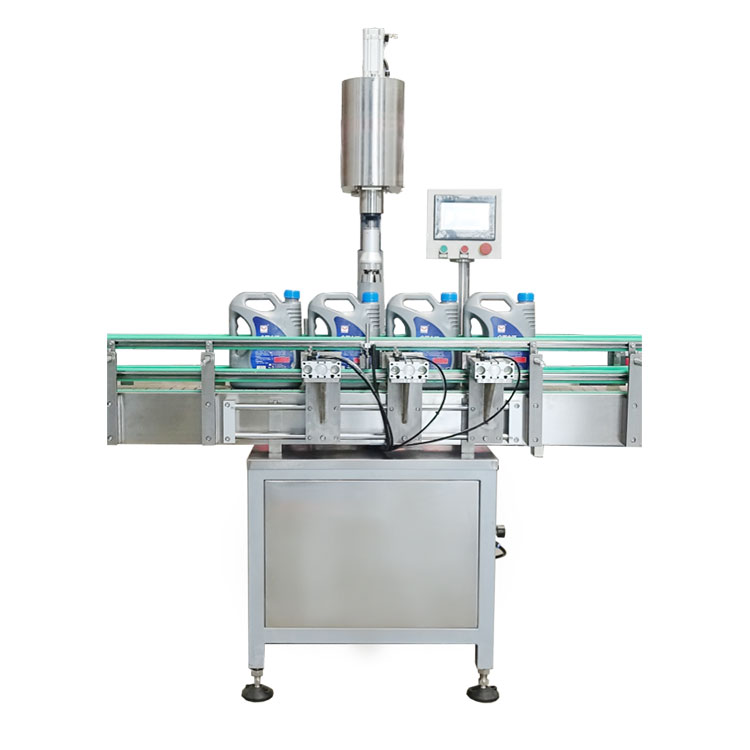

In the fast-paced world of modern manufacturing, efficiency and precision are paramount. The Single Head Cap Screwing Machine has become a cornerstone in the packaging industry, streamlining the capping process and ensuring product quality. This blog will delve into the technological advancements, operational efficiency, and future prospects of this indispensable machine.

Technological Advancements in Single Head Cap Screwing Machines

1. Automation Integration

- Modern Single Head Cap Screwing Machines are equipped with advanced automation features. These machines can be seamlessly integrated into automated production lines, enhancing overall efficiency and reducing human intervention.

2. Smart Controls and Sensors

- The incorporation of smart controls and sensors allows for real-time monitoring and adjustments. These sensors ensure that each cap is applied with the correct torque, and any deviations are immediately corrected, maintaining consistent quality.

3. User-Friendly Interfaces

- With intuitive touch screen interfaces, operators can easily program and monitor the machine's operations. This reduces the learning curve and allows for quick adjustments during production runs.

4. Remote Monitoring and Maintenance

- Some advanced models offer remote monitoring capabilities. This means that operators can oversee the machine's performance from a distance and schedule maintenance proactively, minimizing downtime.

Operational Efficiency of the Single Head Cap Screwing Machine

1. Speed and Precision

- The Single Head Cap Screwing Machine can handle high-speed capping operations without compromising precision. This is crucial for industries with high production volumes, where even a slight delay can impact overall efficiency.

2. Versatile Application

- The machine's ability to handle different types of caps and containers makes it highly versatile. This versatility reduces the need for multiple machines, saving space and investment costs.

3. Reduced Human Error

- By automating the capping process, the Single Head Cap Screwing Machine significantly reduces the risk of human error. This ensures that each product is capped correctly, maintaining the integrity and safety of the product.

4. Energy Efficiency

- Modern machines are designed to be energy-efficient, consuming less power while delivering optimal performance. This not only reduces operational costs but also aligns with sustainability goals.

Future Prospects of Single Head Cap Screwing Machines

1. Integration with IoT

- The future of Single Head Cap Screwing Machines lies in their integration with the Internet of Things (IoT). This will enable even greater connectivity and data analysis, allowing for predictive maintenance and more efficient production planning.

2. Enhanced Customization

- As technology advances, we can expect to see machines that offer enhanced customization options. This will allow businesses to tailor the machine's operations to specific product requirements, improving overall efficiency.

3. Sustainability Focus

- Future developments will likely focus on sustainability. This includes designing machines that use eco-friendly materials and processes, as well as optimizing energy consumption to reduce the carbon footprint.

4. Artificial Intelligence Integration

- The integration of artificial intelligence (AI) will further enhance the capabilities of Single Head Cap Screwing Machines. AI can be used to predict potential issues, optimize operations, and improve decision-making processes.

Conclusion

The Single Head Cap Screwing Machine plays a crucial role in modern packaging, offering unmatched precision, efficiency, and versatility. With continuous technological advancements, these machines are set to become even more integral to the packaging industry. By staying abreast of these developments, businesses can leverage the full potential of Single Head Cap Screwing Machines, ensuring their packaging processes are both efficient and future-ready.

The future of packaging lies in embracing these innovations, and the Single Head Cap Screwing Machine is at the forefront of this evolution. Investing in such technology not only improves current operations but also sets the stage for long-term success and sustainability in the competitive world of manufacturing.