The Shielding Symphony: Galvanization and Color Coating in Steel Corrosion Protection

2023-11-27

Introduction:

In the realm of steel protection, two key players come to the forefront: galvanization and color coating. Together, they form a formidable alliance against the relentless force of corrosion. In this blog, we'll explore the intricate dance between the galvanization process and color coating, understanding how each contributes to the robust shield that preserves steel integrity.

The Galvanization Waltz

1. Immersion in Molten Zinc:

The galvanization process initiates with the steel substrate taking a dip into a molten zinc bath. This immersion creates a metallurgical bond between the steel and zinc, forming a protective layer that acts as a sacrificial anode.

2. Sacrificial Protection:

Zinc has a higher electrochemical potential than steel. In the presence of moisture or corrosive elements, the zinc sacrificially corrodes, shielding the steel beneath from the ravages of rust. This sacrificial protection extends the lifespan of the steel substrate significantly.

3. Uniform Coating Thickness:

The galvanization process ensures a uniform coating thickness, vital for consistent corrosion resistance. This thickness is a critical factor in determining the durability of the galvanized steel against environmental factors.

The Color Coating Pas de Deux

1. Enhancing Aesthetic Appeal:

While galvanization provides a robust defense against corrosion, color coating adds a touch of aesthetics to the functionality. The vibrant hues not only contribute to the visual appeal of structures and products but also serve as a marker of identity in various applications.

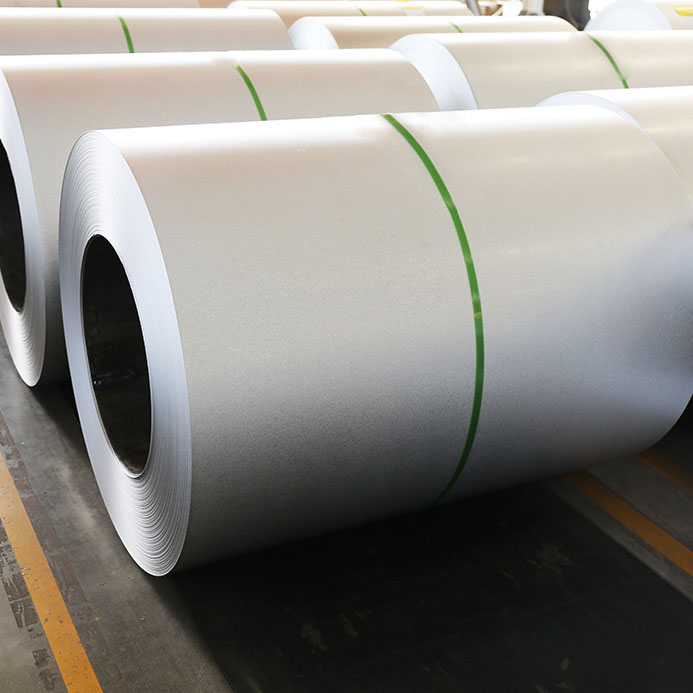

2. Additional Barrier Against Corrosion of color coated galvanized steel coil:

Beyond aesthetics, the color coating acts as an additional barrier against corrosion. It shields the galvanized steel from direct exposure to environmental elements, such as UV radiation, moisture, and pollutants. This extra layer adds a level of protection, complementing the sacrificial nature of the galvanized coating.

3. Customization for Specific Environments:

Different environments demand different levels of protection. Color coatings can be customized based on the specific environmental conditions, ensuring that the steel remains resilient in varied climates and applications.

The Harmonious Union

The true strength lies in the symbiotic relationship between galvanization and color coating. Galvanization establishes the fundamental defense mechanism, while color coating adds a tailored, aesthetic layer of protection of galvanized steel coil. Together, they create a shield that is not only robust but also visually pleasing.

In conclusion, the galvanization process, with its sacrificial protection, forms the foundation of corrosion resistance in steel. The color coating, beyond its role in aesthetics, acts as a guardian, fortifying the steel against environmental challenges. This dynamic duo ensures that steel doesn't just endure; it stands resilient, defying the test of time and the elements.