Unveiling the Art of Corrugation: Achieving Patterns in Single Wall Corrugated Pipes through Extrusion

2024-04-01

In the realm of industrial manufacturing, the creation of single wall corrugated pipes is an art form unto itself. Central to their structural integrity and versatility is the unique corrugation pattern that defines these pipes. But how exactly is this distinctive pattern achieved during the extrusion process? Let's delve into the intricacies of corrugation and uncover the fascinating process behind it.

Understanding Corrugated Pipes

Before delving into the manufacturing process, it's essential to grasp the significance of corrugation in pipes. Corrugated pipes are characterized by a series of parallel ridges and grooves that run along their length. This corrugated structure imparts flexibility, strength, and resistance to external pressures, making them ideal for various applications, including drainage systems, cable conduits, and agricultural piping.

The Extrusion Process: Bringing Corrugation to Life

The extrusion process lies at the heart of corrugated pipe manufacturing, and it's where the magic of corrugation unfolds. Here's a step-by-step breakdown of how the corrugation pattern is achieved:

1. Material Selection: The process begins with the selection of suitable raw materials, typically high-density polyethylene (HDPE) or polypropylene (PP) resin. These materials offer the necessary combination of flexibility, durability, and resistance to corrosion.

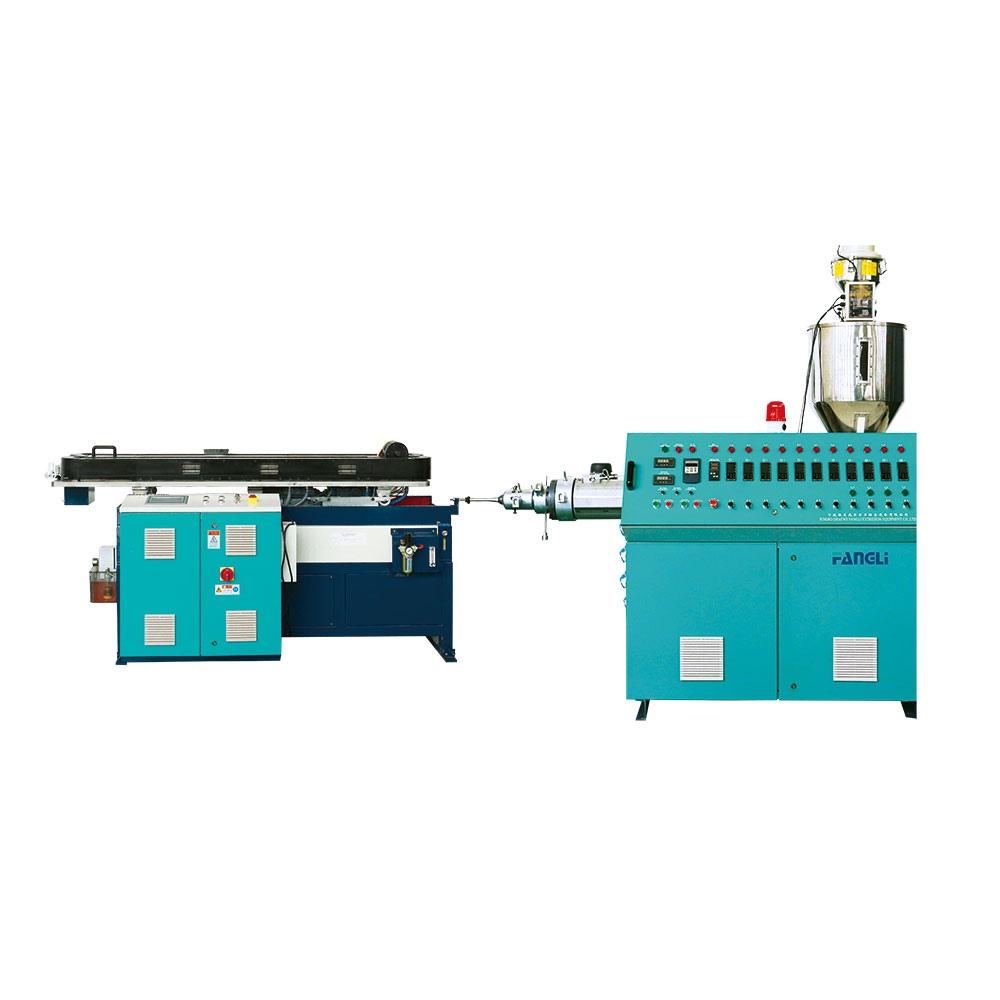

2. Melting and Mixing: The chosen raw material is fed into an extruder, where it undergoes a series of heating and melting stages. During this process, additives such as stabilizers, colorants, and UV inhibitors may be introduced to enhance the properties of the final product.

3. Shaping the Die: As the molten polymer exits the extruder, it passes through a specially designed die head. This die head is precisely engineered to create the desired corrugation pattern. The geometry of the die determines the size, shape, and spacing of the ridges and grooves in the corrugated pipe.

4. Forming in the Corrugator: The extruded polymer then enters the corrugator, a complex assembly of molds or forming plates. These molds impart the desired corrugation pattern onto the still-malleable material. By applying pressure and controlled cooling, the polymer takes on the characteristic ridged structure of corrugated pipes.

5. Cooling and Setting: Once formed, the corrugated pipe passes through a cooling chamber, where it undergoes rapid cooling to set its shape. This cooling process is crucial for ensuring dimensional accuracy and preventing deformation.

6. Cutting and Finishing: Finally, the cooled and corrugated pipe is cut to the desired length and undergoes any necessary finishing processes, such as trimming or chamfering. It is then ready for quality inspection and packaging.

Conclusion: The Artistry of Corrugation

In conclusion, the corrugation pattern in single wall corrugated pipes is not merely a byproduct of manufacturing but a meticulously engineered feature designed to enhance the performance and versatility of these pipes. Through the precise orchestration of heat, pressure, and geometry, manufacturers bring to life pipes that are not only functional but also durable, resilient, and adaptable to a myriad of applications. As we continue to innovate and refine the extrusion process, the artistry of corrugation will remain a cornerstone of modern industrial manufacturing.