Why are blind flanges used in piping systems

2023-11-04

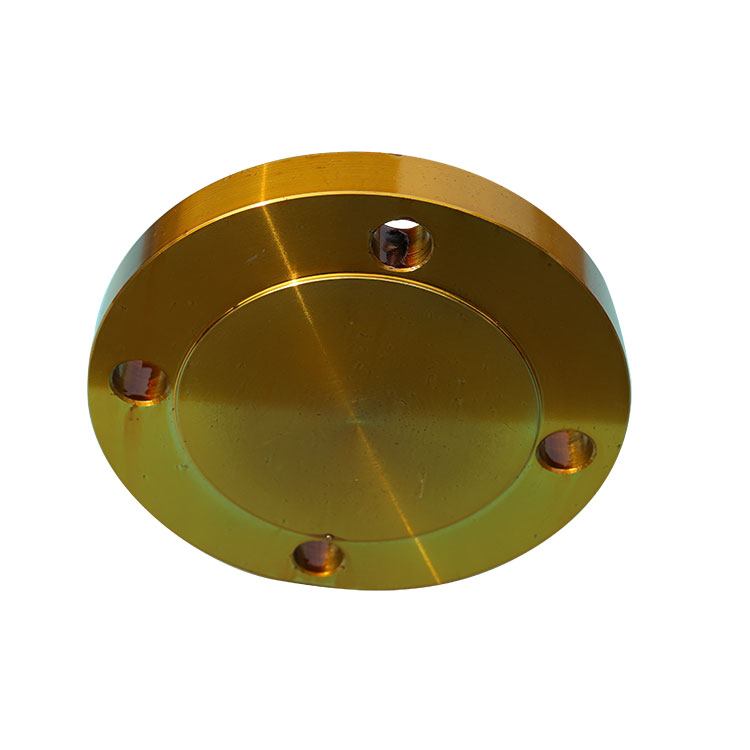

Blind flanges are used in piping systems for several important reasons:

1. Temporary Sealing: Blind flanges are used to provide a temporary seal or closure at the end of a pipeline. This is particularly useful during construction, maintenance, or repair of the piping system.

2. Isolation: Blind flanges are employed to isolate a section of the piping system from the rest of the network. This is especially beneficial when work needs to be done on a specific part of the system without affecting the entire flow.

3. Safety: They are used to prevent the accidental release of hazardous or pressurized materials from the open end of a pipeline, which can be essential for safety in industrial and chemical processes.

4. Inspection and Testing: Blind flanges allow for easy access to the interior of a pipeline or vessel for inspection, cleaning, or testing purposes. They can be removed to perform non-destructive testing or visual inspection.

5. Future Expansion or Connections: In some cases, blind flanges are installed to create a connection point for future piping extensions or branches. This saves time and resources when the system needs to be expanded or modified.

6. Hydrostatic Testing: During the initial construction or testing of a pipeline, blind flanges can be used to temporarily seal off one end for conducting hydrostatic pressure tests to ensure the integrity of the system.

7. Protection: Blind flanges can protect the open end of a pipeline or vessel from debris, contaminants, or environmental factors that could enter and potentially damage the system.

8. Control of Flow: Blind flanges can be used in systems with multiple outlets to control the flow of materials. By sealing off one outlet with a blind flange, the flow can be directed through the remaining openings.

9. Temporary Termination: They can act as temporary terminations in cases where a pipeline or vessel is no longer in use, serving to block off the system safely.

In summary, blind flanges are a versatile component in piping systems, providing a secure closure for various purposes, such as safety, maintenance, isolation, and future expansion. Their ability to be easily installed and removed makes them a valuable tool in managing and maintaining piping systems efficiently.