Why Toughened Polystyrene is Gaining Popularity in Manufacturing

2025-01-03

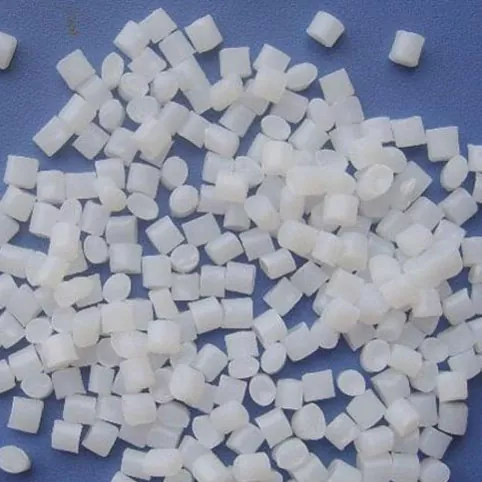

In the world of manufacturing, selecting the right material can make all the difference in terms of performance, cost, and overall efficiency. Toughened polystyrene (TPS), a modified version of conventional polystyrene, is quickly becoming a go-to solution for industries seeking a cost-effective, durable material. This blog will dive into why TPS is gaining popularity in various sectors and how it’s being used to drive innovation in modern manufacturing.

What Makes Toughened Polystyrene Different?

Polystyrene, in its unmodified form, is known for its rigidity but also for its tendency to crack or shatter under impact. This makes it unsuitable for certain high-stress applications. Toughened polystyrene, however, overcomes this limitation by adding rubbery impact modifiers to the base material, which increase its resilience and ability to absorb impact forces.

By combining the low-cost benefits of traditional polystyrene with the added toughness of impact modifiers, TPS strikes a balance that makes it ideal for a wide array of commercial and industrial applications.

Why Manufacturers Are Turning to Toughened Polystyrene:

1. Cost-Effectiveness and Accessibility:

- TPS is an affordable option compared to other impact-resistant plastics, such as polycarbonate or ABS. Manufacturers benefit from its low production costs, which directly translate to lower prices for consumers. This affordability makes TPS an attractive choice for industries with large-volume production needs.

2. Superior Performance Under Stress:

- Toughened polystyrene has been specifically engineered to perform under stress. It resists breaking, cracking, or shattering when subjected to impact, which makes it ideal for applications where durability is critical. Whether in packaging or automotive applications, TPS holds up well under tough conditions.

3. Easy to Process:

- Polystyrene is known for its ease of processing, and this characteristic extends to toughened polystyrene as well. TPS can be molded, extruded, and processed using common techniques, allowing manufacturers to integrate it into existing production lines with minimal adjustments.

4. Versatility Across Industries:

- Toughened polystyrene is used across a wide variety of sectors. From food packaging to consumer electronics to automotive parts, the material’s range of properties—lightweight, cost-effective, and impact-resistant—makes it a versatile solution for manufacturers looking to optimize performance across different products.

5. Environmental Considerations:

- Though not biodegradable, TPS is recyclable, which aligns with the growing demand for sustainable materials in manufacturing. Its recyclability helps reduce waste and supports circular economy principles, making it a more eco-friendly option compared to other plastics that are difficult to recycle.

Applications Driving Growth in Manufacturing:

1. Packaging Solutions:

- One of the largest sectors where toughened polystyrene is making an impact is in packaging. TPS’s ability to resist cracking during shipping and handling makes it ideal for protective packaging. From small electronic gadgets to fragile glassware, TPS helps ensure that products remain intact during transportation.

2. Consumer Electronics:

- The consumer electronics market is another area where TPS is gaining traction. The material is used in the casings of devices such as smartphones, televisions, and computers, where it provides both toughness and a sleek, attractive finish.

3. Automotive Industry:

- In the automotive sector, toughened polystyrene is used for interior trim, dashboards, and other components that require both impact resistance and a clean, polished appearance. Its ability to handle the demands of the automotive environment—ranging from temperature fluctuations to potential impacts—makes it a solid choice.

4. Medical Device Manufacturing:

- The medical device industry relies on materials that are durable, easy to mold, and resistant to breakage. Toughened polystyrene meets these needs, making it an ideal material for creating small but essential components of medical devices.

Toughened Polystyrene is rapidly becoming a cornerstone in modern manufacturing due to its unique blend of durability, affordability, and versatility. As industries continue to seek materials that can deliver both performance and cost savings, TPS offers an ideal solution. With its wide range of applications and ability to meet the demands of various sectors, toughened polystyrene is expected to remain an integral part of manufacturing for years to come.